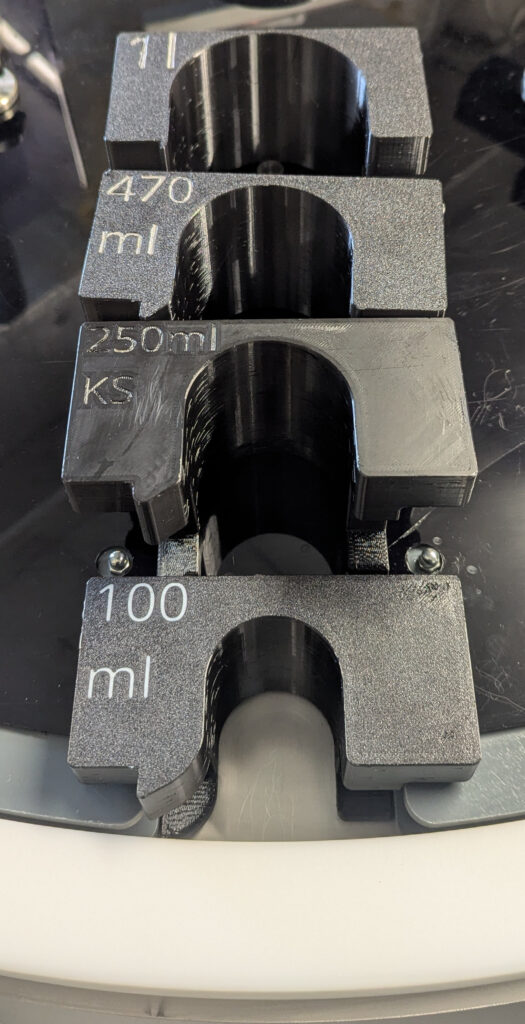

The adapters that now allow for a quick change of format.

The disk that originally had to be changed. It weighs 20kg and has a diameter of 1.5m

Originally the machine was conceived so that a different wheel needed to be inserted for each type of bottle.

Now the wheel stays and the client can swap out adapters if he wants to fill different bottles.

So not only did he save on a new wheel, he now can also change formats much easier.

For a fillilng system we developed a set of adapters that offer the following advantages:

- New bottle formats can be adopted at a much lower cost than when manufacturing a whole new wheel.

- Thanks to 3D printing, new adapters can be made within days. A new disk would need weeks to be manufactured.

- For a product change, the operator can easily swap out 8 adapters. Thanks to magnets he won’t even need tools for the change.

- A product change now takes 5 minutes.

- Originally the whole disk needed to be replaced. Since it weighs 20 kg, this was a two person job.

- In addition to that, the outer rim also had to be swapped out.

- A product change thus took over 30 minutes.