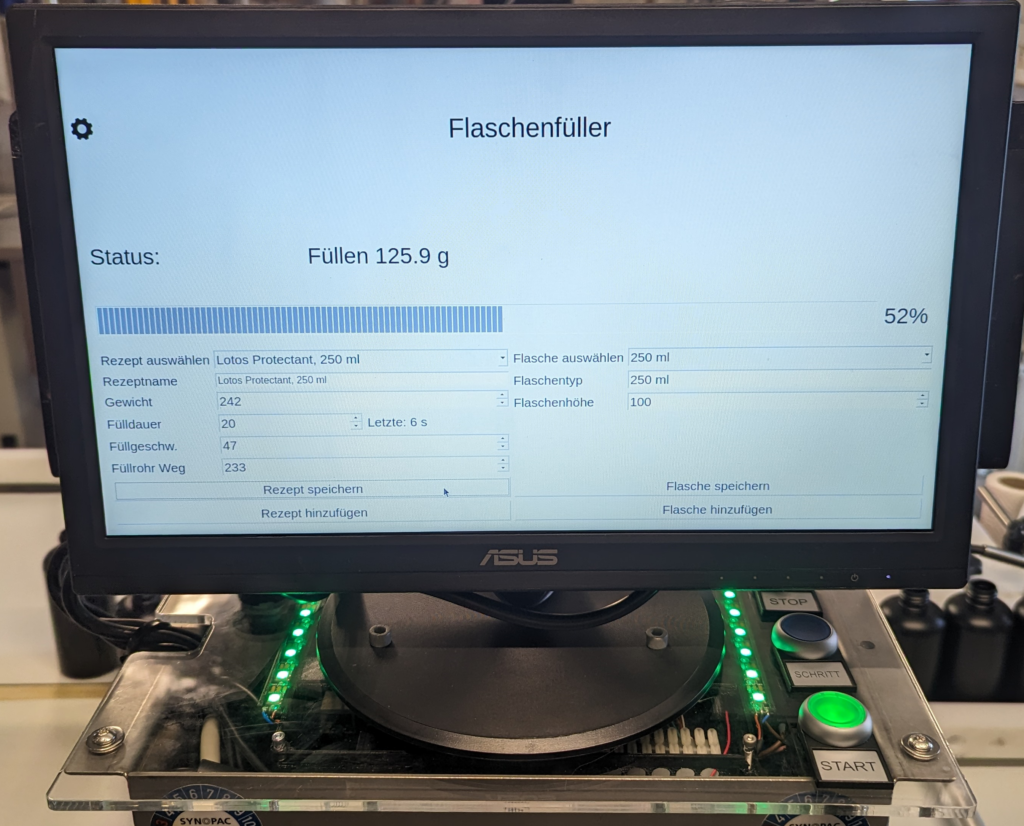

The new touch screen as user interface.

The old user Interface

An overview of the system

The old control system had its weaknesses. It suddenly started overfilling bottles randomly. Since the manufacturer could not solve the issue, the customer contacted us.

We then developed a control system based on a raspberry pi. One part of the control system, based on a Siemens PLC was preserved, seamlessly integrated into the system and still controls the large drives of the machine. The new control system reads the scale and coordinates the linear motion of the filling tube that is lowered into the bottles to fill below level. The tube is retracted proportionally to the fill level to avoid foaming of the product. The raspberry pi also controls the pump for precise dosing of the product.

For the users the operation of the system is now greatly simplified. They have now:

- A system that doesn’t randomly change the fill amount any more.

- A timeout that stops the pump in case the scale fails.

- A graphical interface with a touchscreen instead of the buttons and text displays of the old system.

- A complete recipe management integrated into the user interface instead of having to manually transfer values from a list.

- A better pump that can prime itself.

- LED strips to show the status of the filling system from afar (red/green)